Does Rubber Thickness Really Matter — An Engineering Perspective

When an Australian sourcing engineer raised a question, we decided to share our answer from the engineering side

A Question Worth Answering Properly

Not long ago, a senior sourcing engineer from Australia asked us a deceptively simple question:

“If we want to optimize cost, can we reduce the height of one layer of the wiper rubber? And is wiper noise essentially caused by rubber being too thick?”

We welcomed this question.

Because it goes far beyond pricing.

It touches the core of wiper blade engineering:

How do we balance cost, structure, and real-world wiping performance?

This is not a question that deserves a simple “yes” or “no.”

So we decided to document our internal engineering logic, validation results, and design philosophy—and share them with B2B partners who care about long-term performance, not assumptions.

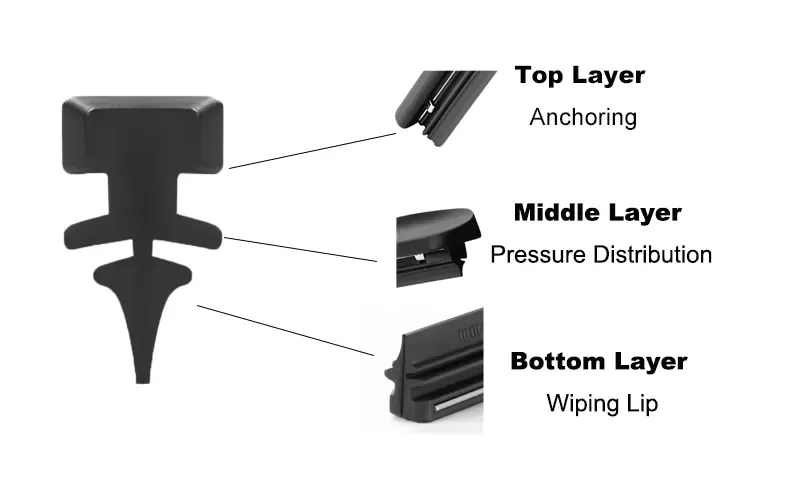

Part 1: Wiper Rubber Is Not “Just Rubber”

From the outside, a wiper rubber may look like a simple extruded strip.

From an engineering standpoint, a high-performance wiper rubber is a multi-layer system, where each layer serves a specific function.

Take our widely used A-Series three-layer rubber structure as an example.

Top Layer: Structural Anchoring

The top layer ensures a secure mechanical connection between the rubber and the metal backing.

Prevents lift under high-speed airflow

Maintains stability under long-term vibration

It does not wipe water directly, but it determines whether the entire system remains stable.

All performance starts here.

Middle Layer: Pressure Distribution Control

(The real key to quiet wiping)

This is the most misunderstood layer.

The force applied by the wiper arm is concentrated.

The job of the middle layer is to transform that force into a smooth, evenly distributed pressure profile along the wiping direction.

Think of it as a pressure management system that:

Absorbs impact

Prevents localized overload

Suppresses chatter and instability

Reducing this layer’s functional space may appear to save cost, but it often disrupts pressure balance—causing localized skipping and impact against the glass.

That is one of the primary sources of noise and poor wiping performance.

Bottom Layer: The Wiping Interface

The lip edge is the most precise part of the rubber.

Geometry defines how the water film is removed

Compound formulation controls friction

However, its performance depends heavily on stable and uniform pressure delivered from the middle layer.

Improving lip material alone cannot compensate for poor pressure distribution.

Why System Balance Matters

Excellent wiper design is not about simplifying individual layers, but about ensuring that each layer fulfills its role within a balanced system.

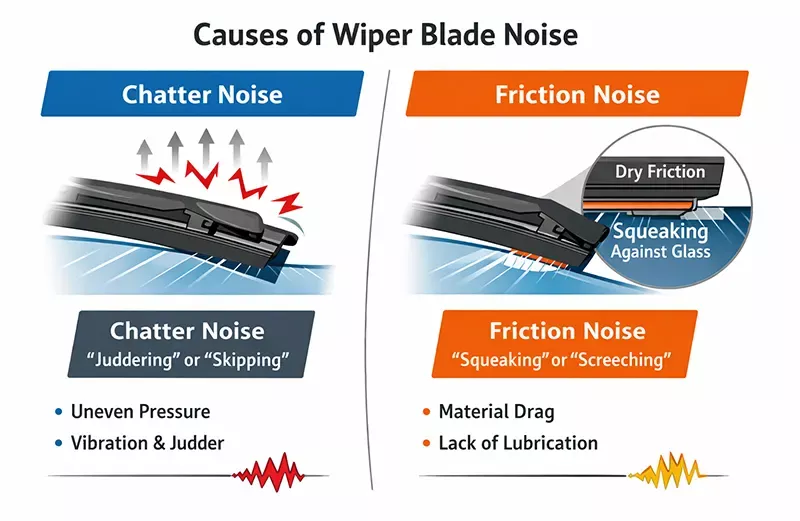

Part 2: The Real Causes of Wiper Noise

Blaming noise on “rubber thickness” is an oversimplification.

Engineering requires identifying root causes.

Based on extensive NVH (Noise, Vibration, and Harshness) testing, wiper noise generally falls into two categories:

Chatter Noise

Characterized by:

Clicking or buzzing sounds

Intermittent vibration

Main drivers include:

Uneven pressure distribution

Insufficient dynamic damping of the material at certain temperatures

Optimizing middle-layer structure and material behavior is far more effective than simply reducing thickness.

Friction Noise

Sharp squeaking sounds caused by interface friction.

This is typically addressed by:

Introducing self-lubricating materials such as graphite or PTFE into the lip compound

Reducing friction over the product’s service life

The Right Path to Noise Reduction

Noise reduction is not about “subtraction.”

It is about smarter optimization:

Pressure distribution curves

Material molecular structure

Lip-edge dynamic geometry

Part 3: When Change Is Required — Our Engineering Validation Approach

We fully understand the market’s demand for cost optimization without sacrificing performance.

The key is not whether to change—but how to change responsibly.

Rather than immediately modifying tooling, we follow a collaborative engineering validation process, supported by our vertically integrated rubber production line and full-system laboratory.

Our Engineering Workflow

1. Requirement Alignment

Define the real objective:

Cost structure optimization?

Noise under specific vehicle or climate conditions?

2. Platform Analysis & Prototyping

Simulations based on material and structural databases

Rapid prototyping on in-house production lines to ensure mass-production consistency

3. Laboratory Validation

Material aging: Ozone and UV exposure

Climate simulation: Extreme temperature and humidity cycles

Durability & NVH: Hundreds of thousands of wipe cycles with continuous noise monitoring

Dimensional accuracy: 2.5D optical measurement to ensure installation compatibility

4. Data-Driven Decision Making

Full test reports, performance comparisons, and cost analysis

Decisions based on lifecycle value, not assumptions

An Invitation to Become “Co-Engineers”

In today’s global automotive supply chain, strong partnerships go beyond transactions.

They are built on:

Respect for engineering logic

Trust in data

A shared commitment to solving complex problems

That Australian engineer’s question was a perfect starting point.

If you are facing wiper noise issues, structural challenges, or cost-performance trade-offs—Bring your questions.

Let’s start from each layer of the wiper rubber and work together, with engineering and data, to find the right balance.

Author: Amy Yang

Contact Email: enquiry@xmyujin.com

Release Time: Dec 17, 2025

Company: Yujin Xiamen Plastic Manufacturing Co., LTD.