A Common Misconception We See Again and Again

When evaluating windshield wiper blades, many buyers—often subconsciously—pick them up and judge quality by weight. The assumption is intuitive: heavier feels stronger, more durable, and therefore better.

From an engineering perspective, however, this assumption does not hold.

After years of OEM manufacturing and aftermarket development, one conclusion has proven remarkably consistent:

Wiper blade performance has no direct correlation with product weight. What truly matters is how intelligently that weight—whatever it is—is engineered into a complete wiping system.

This article explains why weight is a misleading indicator and what actually defines a high-performance wiper blade in real-world use.

Rethinking “Weight”: What It Really Means—and What It Doesn’t

At its core, a windshield wiper has one critical task:

to transfer the force generated by the wiper arm spring evenly and efficiently across the entire rubber blade, so that it maintains stable contact with a curved windshield under all driving conditions.

The Design Paradox of Heavier Wiper Blades

In practice, we often see additional weight used as a shortcut to compensate for structural limitations—for example, thicker low-grade steel frames or bulky plastic components. This can create a solid hand feel, but it rarely solves the real engineering problem.

From our field experience, the outcome is predictable:

Uneven pressure along the blade length

Streaking or partially unwiped areas

Judder, vibration, and noise

Expert insight from the field:

Across years of OEM programs and aftermarket projects, we have repeatedly verified one fact: when customers complain about wiper chatter or poor wiping, the issue is almost never that the blade is “too light.” In virtually every case, the root cause lies in pressure distribution errors or rubber–glass interface design, not insufficient weight.

Engineering analysis supports this observation. Contact pressure uniformity is governed by arm spring force, blade stiffness, and structural geometry, not by mass. Adding weight does not make pressure more even—it often amplifies existing design flaws.

The Hidden Cost of Excess Weight

There is also a system-level consequence that is often overlooked. A heavier blade introduces greater inertia, placing additional load on:

The wiper motor

The linkage and transmission system

Long-term component durability

Especially in high-frequency use or fleet applications, unnecessary weight can shorten system life without delivering any real performance benefit.

The Three Engineering Pillars That Truly Define Wiper Performance

High-performing wiper blades are not heavier by default—they are engineered with purpose. In our experience, performance consistently comes down to three engineering pillars.

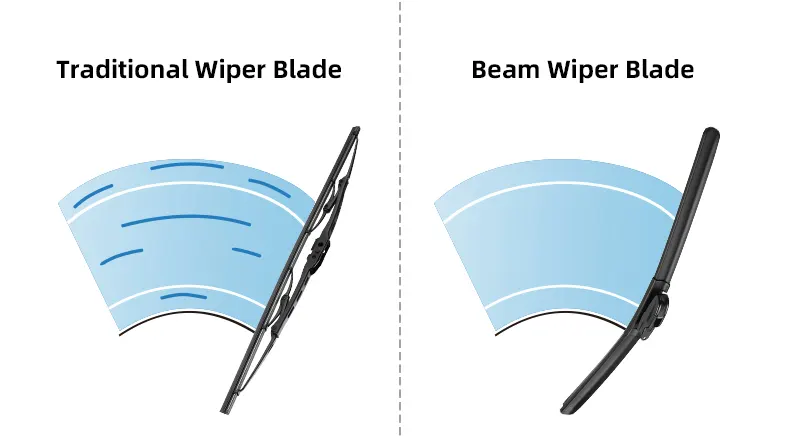

1. Precision Pressure Distribution Across the Entire Blade

The single most important performance factor is how effectively a wiper structure converts one input force from the wiper arm into evenly distributed contact pressure along the full rubber length.

Modern beam and hybrid designs achieve this through continuous load-bearing structures and distributed pressure points—a design approach widely documented in beam blade technology descriptions such as Valeo’s Durabeam beam blade overview. Continuous load-bearing structures

Carefully tuned stiffness profiles

Distributed pressure points that adapt to windshield curvature

Rather than relying on material mass, these designs use calculated elasticity and geometry, validated through CAD/CAE simulation and physical testing. The result is more uniform wiping, reduced noise, and longer rubber life—without unnecessary weight.

2. Aerodynamic Design: Stability at Speed Without Extra Mass

At highway speeds, airflow becomes a dominant factor in wiper behavior. Lift forces can cause instability, chatter, or partial loss of contact.

This is why leading manufacturers such as Bosch and Valeo focus heavily on aerodynamic optimization rather than added mass.

Well-designed, lightweight spoilers:

Convert airflow into a controlled downward force

Stabilize the blade at high speeds

Reduce vibration and wind noise

Lower the load on the wiper motor

Engineering tests and simulations consistently show that aerodynamic downforce is far more effective and predictable than added mass in maintaining stable wiping performance at speed, as discussed in multiple SAE and OEM-level aerodynamic studies.

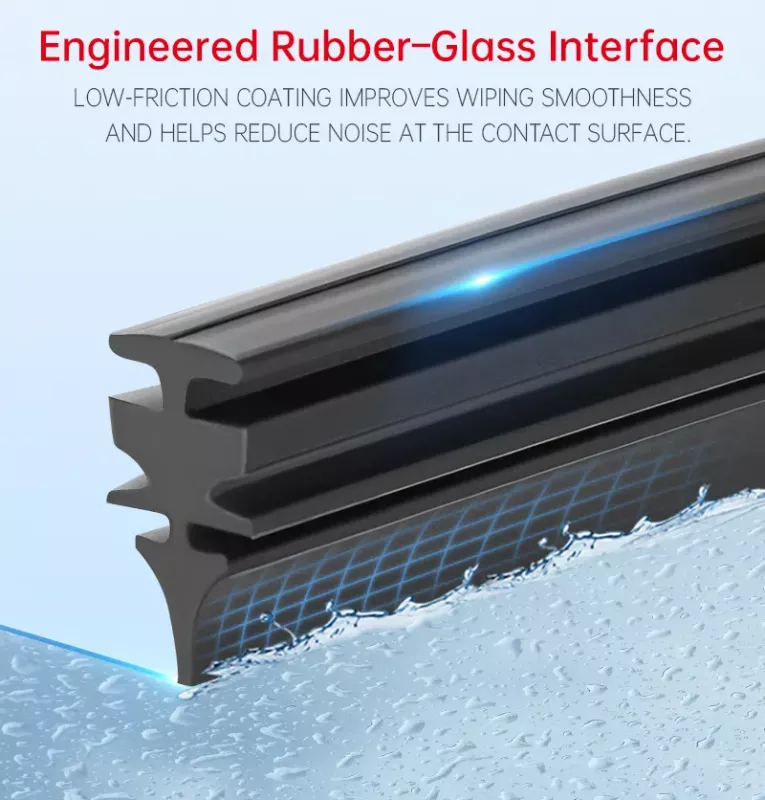

3. Surface treatments and coatings (such as graphite-based or low-friction coatings)

Extensive tribological testing shows that friction behavior and micro-vibration are controlled by material science, not by how heavy the blade feels in hand. A properly engineered rubber profile can deliver clean, quiet wiping across a wide temperature range—regardless of blade weight.

What We See in the Field: A Side-by-Side Comparison

| Evaluation Aspect | Engineering-Optimized Wiper Blade | Traditional Heavy Wiper Blade |

| Design Philosophy | Precise force transmission, aerodynamic optimization | Material thickness over engineering |

| Weight & Balance | Lightweight, compact, well-balanced | Heavier, bulkier |

| Core Structure | High-strength alloys, composite structures, streamlined spoiler | Standard steel frames, minimal airflow consideration |

| Pressure Distribution | Even and consistent along the full blade length | Uneven edge or center lift is common |

| High-Speed Performance | Stable, quiet, no lift or chatter | Susceptible to lift, vibration, and wind noise |

| Impact on Vehicle System | Optimized load, system-friendly | Higher inertia, increased long-term stress |

Our Manufacturing Philosophy: Engineering Value You Can Measure

At BAOYI, we treat every wiper blade as a complete performance system, not a collection of parts.

Science-Driven Development

We follow development processes aligned with global OEM standards, using CAD/CAE simulations and controlled test rigs to evaluate pressure distribution, aerodynamic stability, and durability.

A concrete example:

In one of our wind tunnel validation programs, a vehicle-specific spoiler design generated over 120 grams of additional downforce at 130 km/h, completely eliminating high-speed lift observed in the original design. The improvement came from geometry—not from adding a single gram of unnecessary weight.

Material Innovation With Purpose

Instead of increasing mass, we focus on:

High-performance synthetic rubber compounds

High-strength stainless or alloy steel structures

Lightweight, durable polymer components

This allows us to balance strength, longevity, and efficiency—without compromising system reliability.

Value for Your Brand

For our partners, this engineering-first approach translates into:

Clearer visibility for end users

Quieter, smoother operation

Longer replacement intervals

—all of which directly support a stronger brand reputation and lower warranty risk.

An Invitation to Think—and Engineer—Deeper

The next time you evaluate a wiper blade supplier, look beyond weight and ask the questions that truly matter:

How is uniform pressure distribution achieved and verified?

What aerodynamic features are designed for high-speed stability?

What data supports the rubber compound and coating performance?

A manufacturer who can clearly explain—and validate—these engineering principles is far more likely to deliver long-term value.

And if you have a wiper performance problem that has proven difficult to solve, we invite you to bring it to us. The most effective solutions are always built on engineering fundamentals—not assumptions about weight.

In modern wiper engineering, performance is designed—not weighed.

Author: Amy Yang

Contact Email: enquiry@xmyujin.com

Release Time: Dec 16, 2025

Company: Yujin Xiamen Plastic Manufacturing Co., LTD.