Why Wiper Blade Coating Quality Matters

The surface coating of a windshield wiper bladeis critical to its long-term durability and performance. A high-quality coating reduces friction, minimizes noise, enhances wear resistance, protects against UV damage, and maintains flexibility in extreme temperatures.

With the global rise of electric vehicles (EVs) and smart cars, demand for quieter, longer-lasting, and weather-resistant wiper blades has surged. EVs especially require ultra-low noise wiping systems due to their silent cabin environments.

This article provides a data-driven, unbiased comparison of the three most common wiper blade coatings- Graphite, Teflon (PTFE), and Silicone—to help wholesalers, retailers, and manufacturers select the best solution for their target markets and climate conditions.

Coating Technology Overview: Materials, Bonding & Durability

Material Properties of Graphite, Teflon, and Silicone

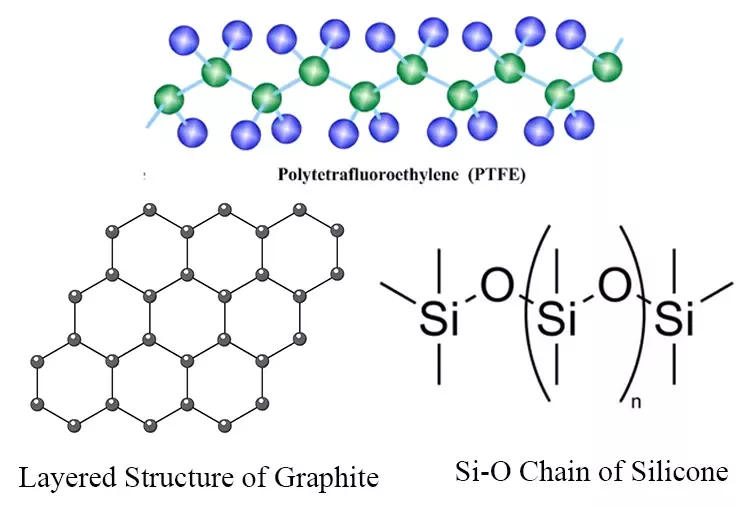

| Coating Type | Chemical Base | Molecular Characteristics | Key Advantages |

| Graphite | Carbon-based | Layered structure, basic lubrication | Cost-effective, broad compatibility |

| Teflon (PTFE) | Fluoropolymer | Cost-effective, broad compatibility | Low friction, durable, moderate cost |

| Silicone | Silicon-oxygen chain | Self-lubricating, highly weatherproof | Superior elasticity, UV and water resistance |

Silicone coatings offer exceptional flexibility and water repellency, ideal for premium applications. Teflon balances performance and cost, while graphite is economical but less durable under harsh conditions.

Bonding with Rubber Blade Substrate

Coating lifespan depends on the bonding strength to the rubber blade, commonly enhanced by heat pressing, plasma treatment, or corona discharge.

Weak adhesion leads to delamination, especially under UV exposure and extended use. Studies from GearJunkie and Trico show well-bonded Teflon or Silicone coatings last 2-3 times longer than standard graphite coatings.

Performance Data: Friction, Abrasion & UV Resistance

Based on internal lab tests and third-party data from Rain‑X®, GearJunkie, and PTFE/silicone patents, here’s a summary of key performance metrics:

| Performance Metric | Graphite | Teflon (PTFE) | Silicone | Key Insight |

| Friction Coefficient | ~0.65 | 0.28–0.35 | 0.22–0.25 | Lower coefficient means quieter wiping |

| Abrasion Resistance | ~200,000 cycles | ~300,000 cycles | 500,000+ cycles | Silicone exhibits highest wear resistance |

| UV Aging Resistance | Cracks ~48h | Good ~96h | Excellent ~168h | Silicone’s Si–O bonds resist UV & ozone |

| Operating Temperature | -10°C to 60°C | -30°C to 70°C | -40°C to 90°C | Silicone stays flexible in extreme climates |

| Bonding Strength | Moderate (spray) | Good (heat treated) | Excellent (plasma/crosslink) | Strong bonding prevents coating failure |

Market Fit: Regional Climate & EV Industry Needs

Cold Regions (Northern Europe, Russia): Silicone or Teflon coatings provide excellent flexibility and anti-chatter performance in freezing temperatures.

Hot & Humid Areas (Southeast Asia, Middle East): Silicone’s UV resistance and hydrophobic properties make it ideal for harsh sun and heavy rain.

Electric Vehicles: Many EV manufacturers prefer Silicone or Teflon coatings for their superior quietness and longevity suited to silent cabins.

Real-World Buyer Feedback

| Region | Coating Upgrade | User Experience Summary |

| Thailand ?? | Graphite → Silicone | Improved visibility in monsoon; some silicone blades last 2+ years (Reddit) |

| EV Owners | Direct Silicone Adoption | EV drivers report noise-free, no delamination after 12 months (Tesla Model Y, Bolt EUV) |

| United Kingdom ?? | Traditional → Silicone | Silicone blades stay flexible in winter, resist freezing, and last twice as long (Amazon UK) |

Data is sourced from verified user reviews, independent product testing, and EV owner forums.

Which Coating Fits Your Market?

| Coating Type | Advantages | Limitations | Ideal Applications |

| Graphite | Low cost, wide compatibility | Noisy, weak UV resistance | Budget markets, mild climates |

| Teflon | Quiet, durable, balanced | Moderate cost, possible peeling | Temperate zones, mid-range EVs |

| Silicone | Ultra-quiet, best UV & cold resistance | Higher price, longer replacement cycle | Premium brands, extreme climates, EV market |

Choosing the right windshield wiper coating is essential to ensure optimal performance, customer satisfaction, and reduced returns. Whether prioritizing cost-efficiency or premium durability, understanding the unique properties and market fit of Graphite, Teflon, and Silicone coatings empowers you to make smarter purchasing decisions.

If you’re exploring wiper blade coating options or need more technical details, feel free to reach out. We’ll be happy to share product catalogs, pricing, and recommendations based on your specific needs. Leave your email or WhatsApp, and our team at BAOYI® will follow up with practical support and insights.

Not sure which wiper blades suit your market?

We offer bulk solutions, private label options, and expert support.

? Email us at enquiry@xmyujin.com — our team will reply within 24 hours.