Across different regions, wiper blades face completely different realities.

For example, a distributor in Canada reports winter brittleness. A buyer in Saudi Arabia complains that the rubber softened during the summer heat. A workshop in Europe returns a batch because the connectors don’t fit as expected.

These are not rare cases—they are the real costs of inconsistent production.

The BAOYI® Lab was rebuilt to eliminate exactly these risks.

Every test, every piece of equipment, and every checkpoint is designed to make sure our partners never have to “guess” which batch will perform well. Instead, the results are stable, repeatable, and ready for global markets.

1. Rubber Durability Begins Long Before Production

The journey starts with the raw compound. Before any rubber enters mass production, it goes through a series of stability checks.

Mooney viscosity and curing behavior are examined to make sure the material will behave consistently during mixing and molding. Hardness, tensile strength, and abrasion resistance are measured so the final blade won’t turn too hard (causing noise) or too soft (causing streaks).

Once the base material passes these checks, samples move into ozone chambers, UV boxes, and temperature-cycling cabinets. These machines compress years of sunlight, oxygen exposure, heat, and frost into a short, controlled test cycle. Rubber that survives this stage without cracking or hardening is trusted to deliver long-term durability in real outdoor use.

This is how we keep batches consistent—even months apart.

2. Verified Performance for Global Climates

A single SKU often ends up in very different markets.

To guarantee that buyers don’t need different models for different countries, every blade is pushed through a wide temperature range inside high-low climate chambers.

The rubber is chilled to sub-zero conditions used to simulate northern winters, then exposed to heat levels similar to Middle Eastern summers. Humidity cycles further accelerate material fatigue.

Only when the blade stays flexible in freezing conditions and avoids softening in heat does it move forward.

This approach allows distributors to confidently supply one SKU across regions like Europe, North America, Southeast Asia, and the Gulf.

3. From Raw Material to Finished Goods: A Complete Quality Loop

After material durability and climate resilience have been confirmed, the focus shifts to how the finished blade performs as a complete product.

Wipers are mounted on fatigue-testing benches and operated through long continuous cycles that simulate years of wiping. During the process, noise levels and wiping stability are closely monitored. This helps ensure the blade won’t chatter or skip after extended use.

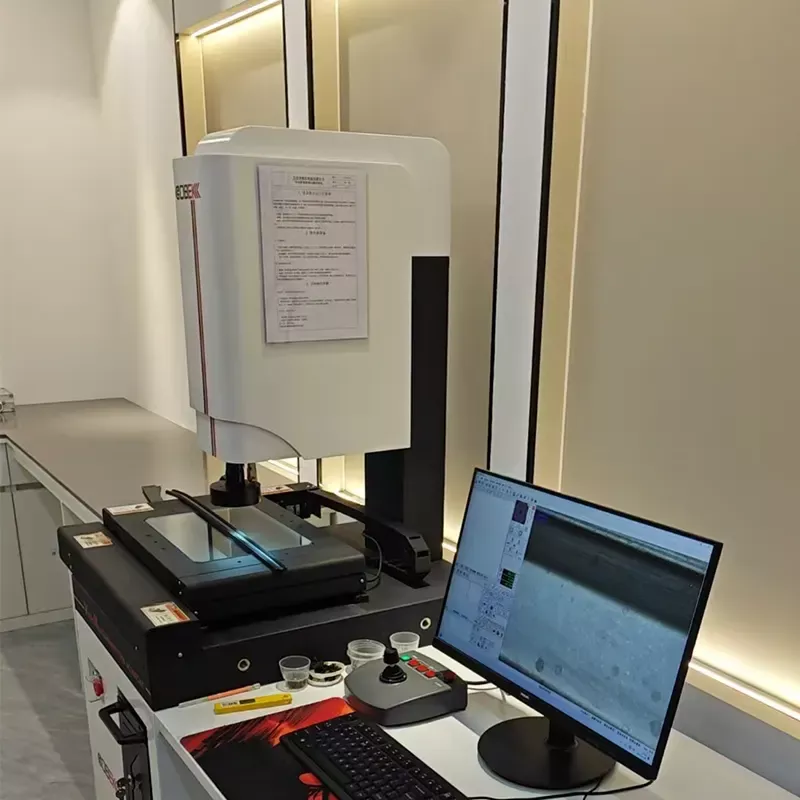

Dimensional precision is then checked using a 2.5D optical measuring system. Connector height, width, angles, and alignment are measured one by one. This final check greatly reduces workshop complaints related to fitment issues, especially for U-hook, side-pin, bayonet, and newer hybrid connector systems.

By the time a wiper reaches packaging, every key point—rubber elasticity, wiping stability, noise, and connector tolerance—has already been verified.

4. The Full Testing Chain

Raw Rubber

→ Viscosity & Curing Analysis

→ Hardness / Tensile / Abrasion Tests

Environmental Testing

→ Ozone & UV Aging

→ Extreme Cold / Heat Simulation

→ Humidity Cycling

Finished Blade Evaluation

→ Fatigue & Noise Testing

→ Precision Measurement

Each step solves a real buyer concern:

batch stability

crack resistance

global climate compatibility

noise control

installation accuracy

This is the full chain that removes guesswork from your procurement.

Reliability You Can Measure

The BAOYI® Lab converts quality from a slogan into a documented, traceable workflow.

Instead of relying on assumptions, every batch is backed by data—material data, climate performance results, durability cycles, and precision measurements.

For you, this means fewer returns, more consistent customer reviews, stronger brand confidence, and the ability to sell our wipers under your own label without hesitation.

When quality is predictable, your business becomes easier to scale.

That’s what our factory full-system lab is built for.

Your next reliable wiper blade supplier starts here.

From OEM projects to bulk procurement, BAOYI® delivers stable quality backed by full-system lab testing.

Author: Amy Yang

Release Time: November 18, 2025

Company: Yujin Xiamen Plastic Manufacturing Co., LTD.