Environmental Compliance – Certified Materials You Can Trust

We carefully select essential raw materials—like steel, rubber, and polymers—from certified global suppliers. All components meet international safety and environmental standards, ensuring smooth export compliance. See full certifications ›

Notably, our steel comes from Bekaert used in our premium oem wiper blades, the same wiper blades wholesale suppliers used by BOSCH and VALEO wiper blades. Our rubber and elastomers, including HYTREL® (TPEE), meet the following environmental standards:

✅RoHS & ELV compliant (no lead, cadmium, mercury, or chromium VI)

✅Free from Ozone Depleting Substances (ODS)

✅Low-VOC content for safe indoor production

✅Tested for GADSL and 94/62/EC packaging compliance

These standards ensure our wiper blades are safe, durable, and ready for global distribution.

? Why it matters: Ensures worry-free clearance in the EU, North America, Japan, and Korea, helping you avoid customs delays and meet importers' regulations.

REACH-Compliant Polymers – No SVHCs Detected

All polymer components used in our products—including Zytel®, GUR®, and Fortron®- are REACH compliant and used in our premium material-enhanced wipers, tested free of SVHCs above 0.1% w/w.

✅We work only with suppliers who meet the Annex XIV Authorization List and register their monomers and additives properly under REACH.

✅ No additional registration required

✅ Fully traceable material sourcing

✅ Suitable for long-term supply chain partnerships

?Why it matters: Minimizes your legal risk in high-regulation markets. Many OEM clients and wholesalers now require REACH documentation during procurement.

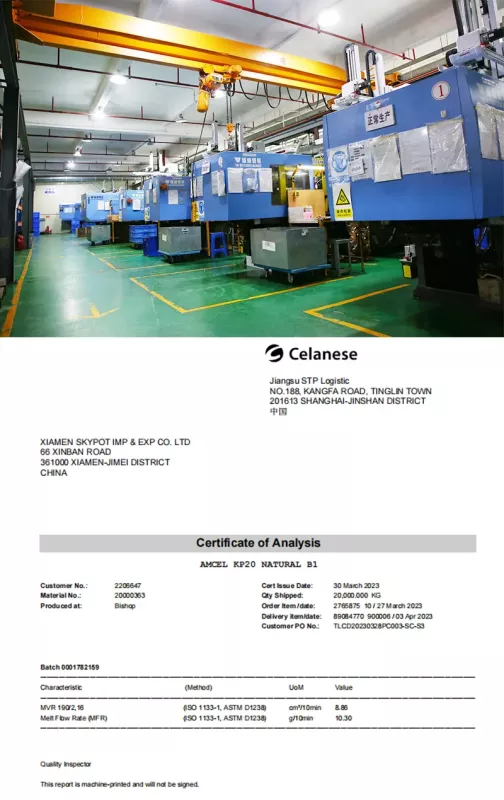

Technical Performance – Certified POM Material (COA Verified)

The key plastic components in our wiper blades are made using Celanese KP20 NATURAL B1 (POM) – a high-strength, fatigue-resistant material with proven injection molding stability.

MFR: 10.30 g/10min, tested to ISO 1133-1

MVR: 8.86 cm³/10min, per ASTM D1238

Production location: Bishop, USA (fully traceable)

Batch-traceable certificate (COA included)

POM ensures excellent rigidity and wear resistance in critical parts such as connectors, adapters, and hinge joints – ideal for long-term durability.

? Why it matters: Consistent injection performance = fewer defects, smoother production, and lower return rates for your aftermarket business.

This means:

✅Consistent injection molding performance

✅Reduced production defects and better fitment

✅Ideal for OEM-quality aftermarket parts

Quality Control – Dual-Layer Assurance System

To maintain high consistency, we’ve built a dual-layer QC process:

1. Raw Material Inspection – before production

2. Final Product Validation – before packaging

All tests are aligned with international automotive standards, performed by our in-house QC team with full traceability from batch to shipment.

Explore our full quality management process, including salt spray, ozone, and fatigue testing.

Trusted by Wholesalers Worldwide

Every material we use is carefully selected and tested to support our wholesale partners with:

✅ Consistent product performance

✅ Globally compliant documentation

✅ Fast customs clearance

✅ Lower return rates and fewer claims

? Whether you distribute to Europe, Southeast Asia, North America, or the Middle East, BAOYI® helps you stay compliant, competitive, and confident.

? Request our latest material certificates for wiper blade components.

Email: enquiry@xmyujin.com, fast response, complete documentation.