Small Problem, Big Risk

For everyday drivers, a faulty low-speed wiper setting may seem like a minor inconvenience. However, for auto repair shops, distributors, and fleet operators, it can quickly become a costly issue:

High return rates: Customers install new wiper blades and find the low-speed function dead—you’re the first call.

Reputation damage: One poor review about “wiper performance” can affect multiple prospective clients.

Hidden costs: Frequent claims and replacements eat into margins, especially for bulk orders.

The root causes typically involve poor motor compatibility or shortcuts on critical components such as resistors, relays, or switches.

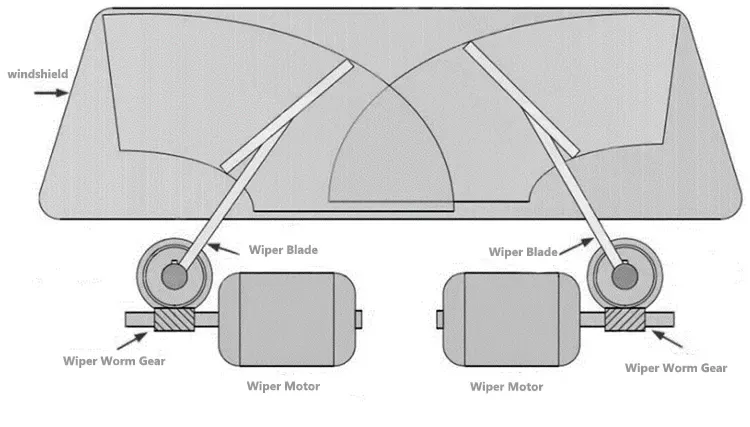

Think of your wiper system as a band. Each part plays a critical role:

Motor = Lead vocalist (drives motion)

Resistor = Bass player (controls low-speed intensity)

Switch = Conductor (issues commands)

Relay = Drummer (handles rhythm changes)

Control Module = Sound engineer (manages smart tuning)

When any component fails, the “band” is left with one loud setting: high speed.

Symptoms: Low-speed wipers don’t respond, but high-speed works normally.

Fix: Replace the resistor with a compatible OEM part.

B-end tip: Offer OEM replacement kits for your clients to prevent repeated service calls.

Symptoms: Low-speed selection doesn’t work, switch feels loose.

Fix: Test and replace the switch if needed.

B-end tip: Provide compatible switch kits and installation guidance for repair shops.

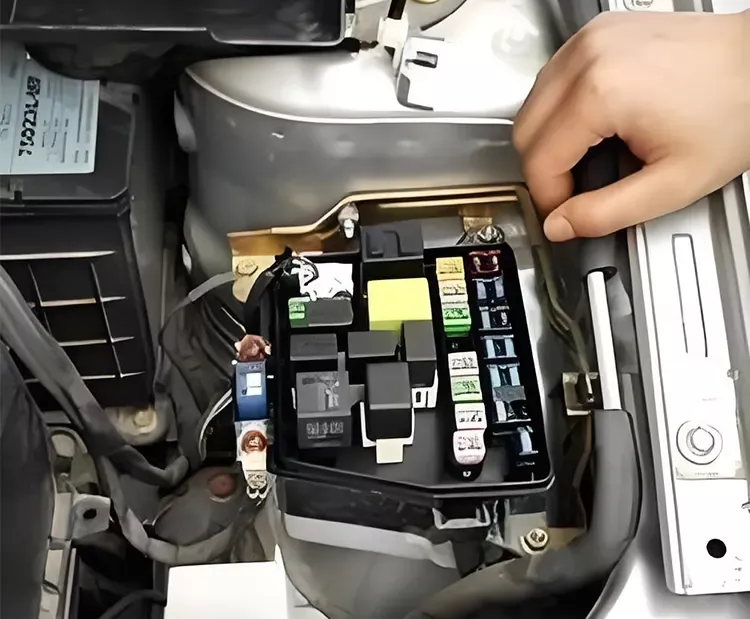

Symptoms: Wipers only operate at high speed.

Fix: Check and replace the relay.

B-end tip: Bundle OEM relays with wiper blades for quick full-speed restoration.

Symptoms: Wipers function intermittently or only on high speed.

Fix: Inspect, clean, and secure all connections.

B-end tip: Include wiring inspection as part of bulk maintenance contracts.

Symptoms: Wipers behave erratically across different speeds.

Fix: Diagnose and replace the module if required.

B-end tip: Provide fully compatible modules for fleet operators to avoid system failures.

| Fault Level | Recommended Action | Estimated Time |

|---|---|---|

| Basic (Resistor/Relay) | Direct replacement | 30–60 min |

| Intermediate (Switch/Wiring) | Clean or repair selectively | 1–2 hrs |

| Advanced (Control Module) | Professional diagnostics required | Varies |

Many wholesalers face repeated low-speed failures after installing new blades. Common causes include:

Mismatched resistor specifications (some models require specific resistance values)

Relay compatibility issues (local vs. imported electrical standards)

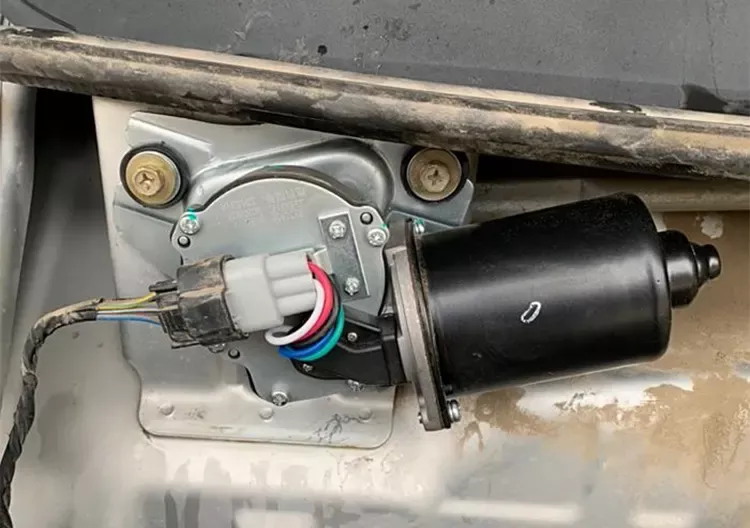

Triple-stage testing before shipment:

Bench simulation under variable voltage

On-vehicle fit testing with popular car models

Road testing in extreme conditions (heavy rain, freezing temperatures)

Flexible compatibility kits:

Adjustable resistors or relay adapters

Optimized installation guides to prevent errors

Guaranteed compatibility: Full-speed functionality, vehicle-specific adapter kits (18 adapters available)

48-hour emergency technical support response

Certified quality: IATF 16949, ISO 9001, over 40 patents

Proven durability: 500,000 wipe cycles without wear, rubber strips exceed GB/T 7762 ozone resistance standards

Vehicle-specific vs. multi-fit compatibility

Rubber vs. silicone material durability

Noise reduction and smooth wiping

Performance in various climates

B-end advantage: Factory-direct supply ensures stable production, consistent specs, and flexible bulk orders

Can a bad relay damage wiper blades? Indirectly, yes. Uneven power can cause premature blade wear. Use OEM replacements to prevent damage.

Should wiper blades be replaced after electrical repairs? Yes. Replacing worn blades ensures optimal system performance and reduces repeated service calls.

Do manufacturers offer bulk supplies for auto shops? Absolutely. Many factories, including BAOYI, support wholesale and fleet orders.

Low-speed wiper failures may seem minor, but they can create hidden costs and customer dissatisfaction for B-end operators. Pairing electrical repairs with high-quality BAOYI OEM wipers guarantees reliable performance and long-term client satisfaction.

OEM & private label support | Bulk / wholesale supply | Stable factory capacity | Global aftermarket experience

👉 Contact us to discuss your wiper blade sourcing requirements.